Protection classes

The protection class (IP) of a device uses two numbers and possibly an additional letter to describe how the housing is protected against foreign bodies, contact and moisture:.

The first number indicates how good the protection against foreign bodies is

The second figure determines the degree of insulation against contact and moisture

Higher numbers mean higher protection. In the table below you will find an overview of the protection classes used in our products and their meaning.

| Protection class | Foreign objects | Touch | Moisture |

| IP20 | (2) Protected against solid foreign bodies with a diameter of 12.5 mm or more |

Protected against access with a finger (230 V) For LED light strips: no protection against contact |

No protection |

| IP44 | (4) Protected against solid foreign bodies with a diameter of 1 mm or more |

Protected against access with a wire |

Protection against splashing water on all sides - for recessed LED spotlights only when installed |

| IP55 | (5) Protected against dust in damaging quantities |

complete protection against contact. For LED light strips: no protection against electrostatic damage to the product |

Protection against water jets (nozzle) from any angle |

| Nano (not official) |

(-) Dust-tight |

complete protection against contact. For LED light strips: no protection against electrostatic damage to the product |

Protection against moisture and occasional dripping water if the housing (the light strip) is inclined at least 15° and the water can drain away immediately |

| IP65 | (6) Dust-tight |

Complete protection against contact |

Protection against strong water jets |

| IP65 | (6) Dust-tight |

complete protection against contact. For LED light strips: conditional protection against electrostatic damage to the product |

Protection against temporary immersion in fresh water for up to 30 minutes - no protection against seawater |

The importance for electronic components

We offer electronic components in protection classes: IP20 | IP65 | IP67.

IP20 may only be operated in dry and frost-free rooms. This does not include, for example, a garage or an uninsulated and unheated cellar / attic. Condensation regularly forms there due to fluctuations in temperature and humidity, leading to corrosion and premature failure of the appliance.

However, these devices can optionally be used in an appliance box if it has at least IPx4 protection.

IP65 | IP67 can be used in damp rooms and outdoors. In contrast to IP65, IP67 can be installed in rainy areas and can also be briefly immersed in fresh water. In principle, IP65 should be protected against direct exposure to rain and rising water.

The importance of iluminize recessed spotlights

Recessed spotlights are usually installed in a ceiling construction. When not installed, they usually have protection class IP20, so they are not well protected. Neither from dust, moisture nor from contact with a wire. Once they are installed in the ceiling, and the designs only apply to fully recessed spotlights, they usually have protection class IP44 when viewed from below. Due to the protective effect of the ceiling, dust and moisture cannot penetrate to the electrical components of the spotlight.

The importance of LED light strips

LED light strips are very sensitive and the usual protection classes are difficult to apply.

The situation is clear for light strips with protection class IP20. These are not protected and must not be exposed to any external influences. They must not be touched (when energised) or operated in a damp environment.

The light strips with IP67 are well protected against contact and water ingress. However, the protective sheath does not prevent electrostatic shock and thus damage to the product if the light strip is connected to the power supply and touched by a charged person.

The IP Nano protection class defined by us is not an official protection class. We have defined it because there is no equivalent in the IP system.

In outdoor areas, further conditions must be taken into account. In particular, the protective layer gradually becomes permeable under the influence of UV radiation, see the section on UV radiation below.

We therefore recommend that the light strips are always mounted in an aluminium profile rather than exposed. Even in the shade, for example in a canopy, there is a considerable and destructive level of UV radiation.

Installation in the shower

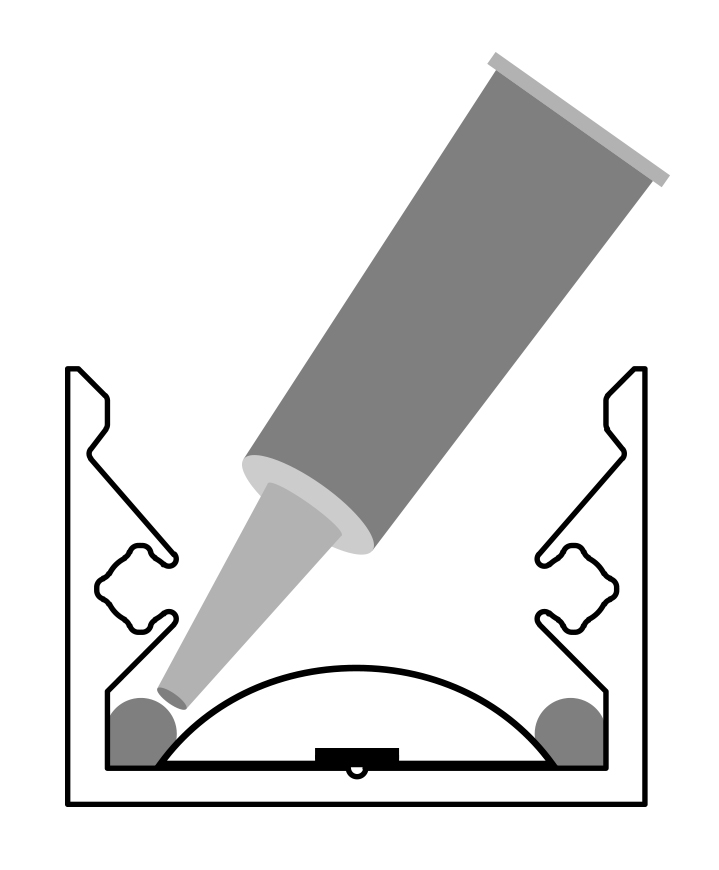

In places in the shower area where the aluminium profiles are flooded with water, small amounts of water penetrate the profiles due to the capillary effect and gradually accumulate there. This particularly affects the vertically installed profiles with LED light strips.

The profiles should therefore be given a drain at the bottom, for example with a diffuser that is 1-2 mm shorter. Make sure that the water that has penetrated cannot flow backwards towards the wall.

To prevent water from penetrating behind the light strip, you should also use silicone to create a joint to the right and left of the light strip, as shown in the picture. This applies in particular to the nano-coated light strips.

Special features

UV radiation

Protective coatings on LED light strips are destroyed by UV radiation over time. This applies equally to the nano-coating and the silicone coating (IP67). The much thinner layer thickness of the nano-coating, which is only a few micrometres, leads to damage within days when exposed to sunlight.

The protective effect, especially against penetrating moisture, decreases. Initially, individual areas become permeable and the layer is no longer tight. As a result, the light strip corrodes due to moisture penetrating from the inside.

Mounting the LED light strip in an aluminium profile with a diffuser made of PPMA significantly delays this effect, so that LED light strips will function for years without any problems if they are optimally mounted.

Sea water and air, chlorine and ozone

All products offered here are not permanently protected from sea air, seawater, chlorine and ozone, unless explicitly stated. In outdoor areas on the coast and around swimming pools, further protective measures must be taken to ensure that the products remain functional.

Installation in aluminium profiles delays the destruction process, but can only prevent it if the profile is completely sealed against penetrating air. Chlorine and ozone in particular penetrate easily through the small gaps and capillaries on a profile and carry out their destructive work there.